|

| |

| Range of Application |

Materials |

| Pressure |

- 700mm (HG) |

Metals |

-DIN 1.4571, 316SS |

| |

- 12 bar |

|

-Hastelloy C |

|

Springs

Faces

O-Rings |

-Hastelloy C6

-CA, SC,

-Viton, EPDM |

| |

|

|

|

| Sizes |

|

|

|

| Dshaft |

-50.....140mm, -2".....5 1/2 "

|

|

|

|

|

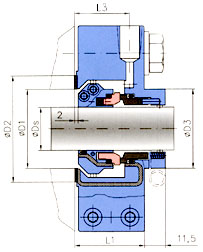

Split , space saving design.

|

- No dismantling of equipment necesary

|

No stuffing box room required since the complete seal is mounted within its own housing on the outside.

|

- Simple change over from packings to mechanical seals possible.

|

Large cavity available above the seal faces. Solids or slurry particles will be thrown away from the seal faces by cenrifugal force.

|

- Reliable application also with solids containing fluids.

|

Mounting splints retain the spring tension. When mounting is completed the splints will be removed and the spring force will be applied to the stationary seal face.

|

- Simple and easy installation.

|

Style 390 split O-rings with integrated cantering and connecting splints are an absolute novelty with regard to split seals.

|

- Quick, reliable and precise mounting possibilities.

|

Gland Centering pieces do not have to be extracted or removed after installation.

|

- Additional safety for easy installation procedure.

|

Fitting appliances for linear mounting are part of the scope of supply.

|

- Makes installation much easier!

|

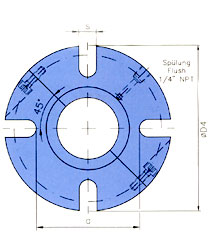

| 1/4" NPT flush connection for axial fush possibility. |

- Effective alternative for sealing medias with solid content.

|

| Stationary/Balanced Design |

- Reliable working conditions with lowest possible face load for longest possible service life.

|